Pig iron is the term that is generally applied to a metallic product that contains over 90% iron. Typically, it contains approximately 3% carbon, 1.5% silicon and lesser amounts of manganese, sulfur and phosphorus. Pig iron along with scrap metal is the base material for both cast iron and cast steel.

White Cast Iron

Chilled cast iron is produced by casting the molten metal in such a way as to produce a surface virtually free of graphitic carbon. The surface of chilled iron castings is extremely hard. The depth and hardness of the chilled portion may be controlled by adjusting the composition of the metal.

White iron is a type of chilled cast iron that is virtually free of graphitic carbon, which is achieved by selecting a specific chemical composition to inhibit graphitization for a given section size. The hardness of the casting may be controlled by selection of composition.

In both chilled and white irons, the depth of chill decreases and the hardness increases with increasing carbon content. Carbon varies from 2.5% to above 3.5%. It also is necessary to control silicon content; the chill is reduced by increasing the silicon content. The range of silicon content for white irons is governed by the section size. Silicon content varies from 0.6-1.5%. Alloying elements such as nickel, chromium and molybdenum are used to improve wear resistance.

Malleable Iron

Malleable irons are relatively soft and can be bent without breaking. They include ferritic (or standard) malleable iron and pearlitic malleable iron. Malleable iron is obtained by the heat treatment of white iron, so the hard iron-carbide structure of ledeburite is converted to a matrix of ferrite or pearlite and graphite, the latter being precipitated within the iron. This form of graphite is sometimes referred to as tempered carbon. A wide range of mechanical properties can be obtained in malleable iron with different matrix structures around the graphite.

Ferritic malleable iron has a ferrite matrix with interspersed nodules of tempered carbon and, depending on how it is produced, some combined carbon. Pearlitic malleable iron is designed to have combined carbon in the matrix, resulting in higher strength and hardness than ferritic malleable iron. The malleable irons typically contain from 2.0-2.65% C, 0.90-1.65% Si and 0.25-0.55% Mn as major constituents.

Gray Iron

Gray irons are alloys of iron, carbon and silicon, in which more carbon is present than can be retained in solid solution in austenite at the eutectic temperature. The carbon precipitates as graphite flakes. The gray irons typically contain from 1.7-4.5% carbon and 1-3% silicon as major constituents.

Ductile Iron

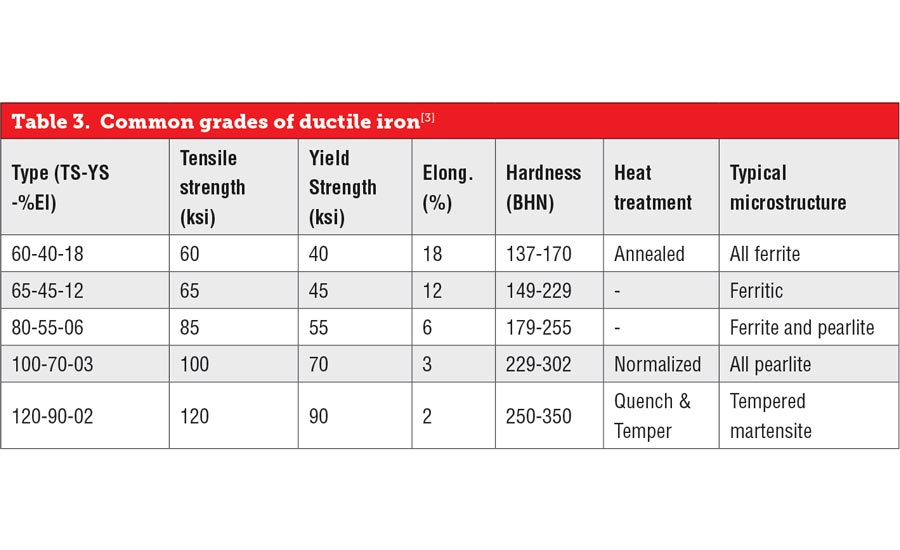

Ductile or nodular iron, also known as spheroidal graphite iron, is cast iron in which the graphite is present as tiny balls, or spherulites, instead of graphite flakes (as in gray iron) or compacted aggregates (as in malleable iron). The nodular irons typically contain from 3.2-4.1% C, 1.8-2.8% Si and up to 0.80% Mn as major constituents. Several types of matrix structures (including ferritic and pearlitic) can be developed by alloying and heat treatment. The various grades of regular, unalloyed ductile iron are designated by their tensile properties (Table 3).

ABOUT KEVA

Keva Casting is a professional casting company that focuses on Construction, Machinery, Automobile, Hardware, Pipeline and many other industries.

We provide top quality products with the best service based on our complete production chain including our own mold design, advanced production techniques, and full management of the supply chain. Keva Casting has two factories located in Zhucheng, China's Shandong province.

We use "shell molding", which is a new technique that has been developed in recent years.This new technique has simplified production procedures and reduced air pollution compared with traditional sand casting and investment casting. Shell making and core making are faster to ensure production in enormous quantities. The dimensions and surface finishing are satisfactory for all kinds of industrial requirements. Besides supplying our own formwork & scaffolding systems, our casting products also supply OEM services in various industries.